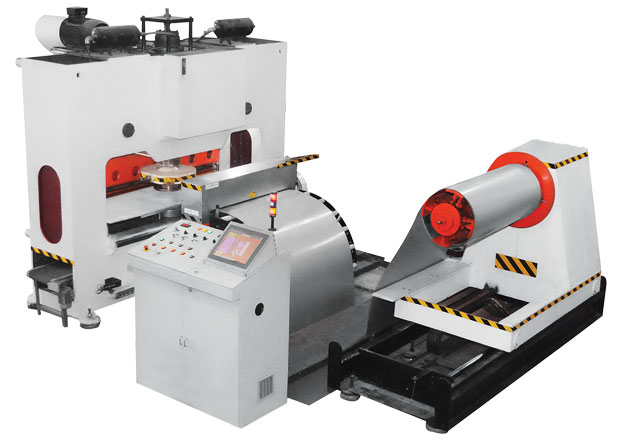

PRESS:

Robust construction H-type ring frame press for utmost rigidity and accuracy. A scotch yoke mechanism slide with three long guide & slide length of 1400mm which offers extreme accuracy for your tools resulting in a longer tool life.

Moreover, all gears , slides , crank , bushes & bearing run in oil bath for optimum long life & maintenance free operations.

FEEDER:

.jpg) Driven by computerised numerically controlled(CNC) panel and servos from Panasonic, our feeders deliver the precise movement of the coil at a very high speed with an accuracy of up to 0.1mm and linear speed of up to 50m/min.

Driven by computerised numerically controlled(CNC) panel and servos from Panasonic, our feeders deliver the precise movement of the coil at a very high speed with an accuracy of up to 0.1mm and linear speed of up to 50m/min.

Heavy linear motion guideways and accurate ball screws are used for fast and long lasting performance.

A combination of two different materials for the feeding rolls is used to have zero frictional loss and scratchless blanks.

Also the self centring coil guiding system for time saving.

The very user friendly software provided for the blanking line adjusts itself for the blank size and coil width input by the user to give minimum optimum scrap wastage.

SLITTING LINE:

.jpg) For those who require maximum coil recovery for their blanking solutions, we have introduced on-line slitting. After decoiling, coil gets slitted and is fed to the press for blanking operation. This way one can do the slitting operation as well as blanking operation in a single line for maximum coil recovery of up to 92%.

For those who require maximum coil recovery for their blanking solutions, we have introduced on-line slitting. After decoiling, coil gets slitted and is fed to the press for blanking operation. This way one can do the slitting operation as well as blanking operation in a single line for maximum coil recovery of up to 92%.

SCRAP HANDLING:

.jpg) Scrap chopper mounted at the frame of the press shears the scrap in a neat manner at a speed of up to 65 strokes/minute.

Scrap chopper mounted at the frame of the press shears the scrap in a neat manner at a speed of up to 65 strokes/minute.

Not just for scrap, the chopper can also be used as a cut-to-length. The chopper itself can be used as a shearing machine for the coil width of up to 1600mm.

Scrap coiler can also be used as rewinding of the scrap after the blanking operation with speed of the press.

COIL HANDLING:

Heavy duty decoilers are used in different sizes depending upon the customer’s requirement i.e with tonnage capacities varying from 3 to 10 tons.

Features like coil cart and hydraulic coil locking at the touch of a button saves time.

| |

BL 15″/700 |

BL 20″/1300 |

BL 24″/1300 |

BL 28″/1600 |

| SPECIFICATIONS |

|

|

|

|

| Capacity (tons) |

80 |

80 |

125 |

150 |

| Max’m Coil Width(mm) |

700 |

1300 |

1300 |

1600 |

| Max’m Circle Size |

15″ (380mm) |

20″ (510mm) |

24” (610mm) |

28″ (712mm) |

| strokes per minute |

120 |

120 |

60 |

60 |

| FEATURES |

|

|

|

|

| User interface |

hmi |

hmi |

scada |

scada |

| Conveyor |

optional |

yes |

yes |

yes |

| Coil Cart |

optional |

optional |

optional |

optional |

| Hydraulic Coil Clamp |

optional |

optional |

optional |

optional |

| with Slitting Line |

NA |

optional |

optional |

optional |

| Strap Winder (recoiler) |

optional |

optional |

optional |

optional |

| Scrap Chopper |

NA |

NA |

optional |

optional |

.jpg) Driven by computerised numerically controlled(CNC) panel and servos from Panasonic, our feeders deliver the precise movement of the coil at a very high speed with an accuracy of up to 0.1mm and linear speed of up to 50m/min.

Driven by computerised numerically controlled(CNC) panel and servos from Panasonic, our feeders deliver the precise movement of the coil at a very high speed with an accuracy of up to 0.1mm and linear speed of up to 50m/min..jpg) For those who require maximum coil recovery for their blanking solutions, we have introduced on-line slitting. After decoiling, coil gets slitted and is fed to the press for blanking operation. This way one can do the slitting operation as well as blanking operation in a single line for maximum coil recovery of up to 92%.

For those who require maximum coil recovery for their blanking solutions, we have introduced on-line slitting. After decoiling, coil gets slitted and is fed to the press for blanking operation. This way one can do the slitting operation as well as blanking operation in a single line for maximum coil recovery of up to 92%..jpg) Scrap chopper mounted at the frame of the press shears the scrap in a neat manner at a speed of up to 65 strokes/minute.

Scrap chopper mounted at the frame of the press shears the scrap in a neat manner at a speed of up to 65 strokes/minute.